Mar. 25, 2014

Toyota Motor Corporation

Yazaki Corporation

Toyota Tsusho Corporation

Yazaki Corporation

Toyota Tsusho Corporation

Toyota and Partners Develop Pioneering Vehicle-to-Vehicle Copper Recycling Technology

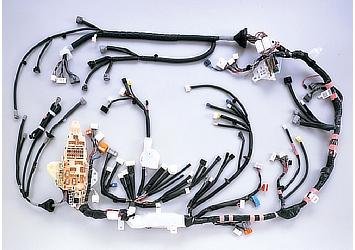

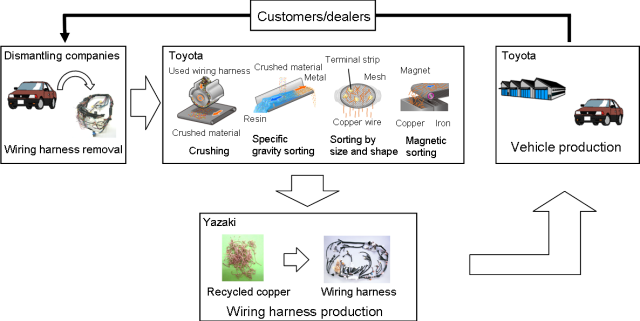

Toyota City, Japan, March 25, 2014―Toyota Motor Corporation (TMC) has developed a world-first technology for recycling the copper contained in wiring harnesses, in collaboration with Yazaki Corporation (Yazaki), Toyota Tsusho Corporation (Toyota Tsusho), and eight other companies. The newly-developed technology produces copper with a purity of 99.96 percent.

Roughly 40 years’ worth of mineable copper resources*1 remain worldwide, while global consumption is growing, driven particularly by infrastructure-related demand for wiring in emerging markets. In addition, large amounts of copper are used in the motors of hybrid vehicles, which are becoming increasingly popular.

When wiring harnesses are removed from end-of-life vehicles under conventional methods, it is extremely difficult to separate the copper from the fuse box and other components. As a result, it has not been possible until now to recycle harnesses using mechanical sorting methods*2.

In 2010, however, TMC, Yazaki, Toyota Tsusho and their partners*3 began collaboration in a number of areas, including establishing pre-processing quality requirements for dismantling companies. In 2011, TMC developed the first mechanical sorting method that can prevent contamination from minute impurities. Trial production involving small amounts of recycled copper began at TMC’s Honsha Plant in 2013. Once quality had been assessed by Yazaki, the copper was introduced to the wiring harness manufacturing line. Stable production involving recycled copper has been achieved, and annual production of recycled copper using this method will increase to approximately 1,000 tons in 2016.

This new technology is the result of TMC’s first collaboration with parts makers and dismantling companies in Japan on next-generation recycling systems. Toyota will continue to enhance this technology while reducing costs and expanding collaborative efforts. Furthermore, Toyota will create an ongoing next-generation recycling project with parts makers and dismantling companies with the aim of fostering a recycling-based society. This, in addition to other resource recycling initiatives, will become a new source of competitiveness for Toyota and other involved companies as they combat resource depletion.

Roughly 40 years’ worth of mineable copper resources*1 remain worldwide, while global consumption is growing, driven particularly by infrastructure-related demand for wiring in emerging markets. In addition, large amounts of copper are used in the motors of hybrid vehicles, which are becoming increasingly popular.

When wiring harnesses are removed from end-of-life vehicles under conventional methods, it is extremely difficult to separate the copper from the fuse box and other components. As a result, it has not been possible until now to recycle harnesses using mechanical sorting methods*2.

In 2010, however, TMC, Yazaki, Toyota Tsusho and their partners*3 began collaboration in a number of areas, including establishing pre-processing quality requirements for dismantling companies. In 2011, TMC developed the first mechanical sorting method that can prevent contamination from minute impurities. Trial production involving small amounts of recycled copper began at TMC’s Honsha Plant in 2013. Once quality had been assessed by Yazaki, the copper was introduced to the wiring harness manufacturing line. Stable production involving recycled copper has been achieved, and annual production of recycled copper using this method will increase to approximately 1,000 tons in 2016.

This new technology is the result of TMC’s first collaboration with parts makers and dismantling companies in Japan on next-generation recycling systems. Toyota will continue to enhance this technology while reducing costs and expanding collaborative efforts. Furthermore, Toyota will create an ongoing next-generation recycling project with parts makers and dismantling companies with the aim of fostering a recycling-based society. This, in addition to other resource recycling initiatives, will become a new source of competitiveness for Toyota and other involved companies as they combat resource depletion.

Vehicle-to-vehicle copper recycling for wiring harnesses

| Eight dismantling companies involved in collaboration |

| Company name | Representative | Location |

|---|---|---|

| Auto Recycle Sanri | Daigo Kato | Toyota City, Aichi Prefecture |

| Johoku Jidosya Kogyo Co., Ltd. | Tatsuo Kanemura | Kasugai City, Aichi Prefecture |

| Kawaguchi Shouten Co.,Ltd. | Norio Kawaguchi | Okazaki City, Aichi Prefecture |

| Kobayashi-shouten Inc. | Nobuo Kobayashi | Tsu City, Mie Prefecture |

| Marudai Corporation | Masahiro Yamaguchi | Ina City, Nagano Prefecture |

| Morita Sharyo Corporation | Katsuyuki Morita | Handa City, Aichi Prefecture |

| New Iwata Corporation | Noriyuki Iwata | Ichinomiya City, Aichi Prefecture |

| Yamauchi Shoten Co., Ltd. | Eiichi Yamauchi | Inazawa City, Aichi Prefecture |

| *1 | According to Japan Oil, Gas and Metals National Corporation (JOGMEC), “Copper Demand Trends,” January 31, 2013 |

| *2 | Sorting methods whereby the wiring harness covering is removed by a shredding company, aluminum and other light metals are removed by a method called specific-gravity sorting, iron is removed magnetically, and small contaminants are identified by color and removed. |

| *3 | Eight dismantling companies from the Chubu region of Japan |