Dec. 11, 2017

The Story Behind the Birth of the Prius, Part 1

It is not a stretch to say that for many people, the word "Prius" comes to mind when they hear the word "hybrid." The Prius has become so widely known that it is nearly synonymous with hybrid cars.

But what's the story behind the Prius? Just how did this revolution in car-making begin?

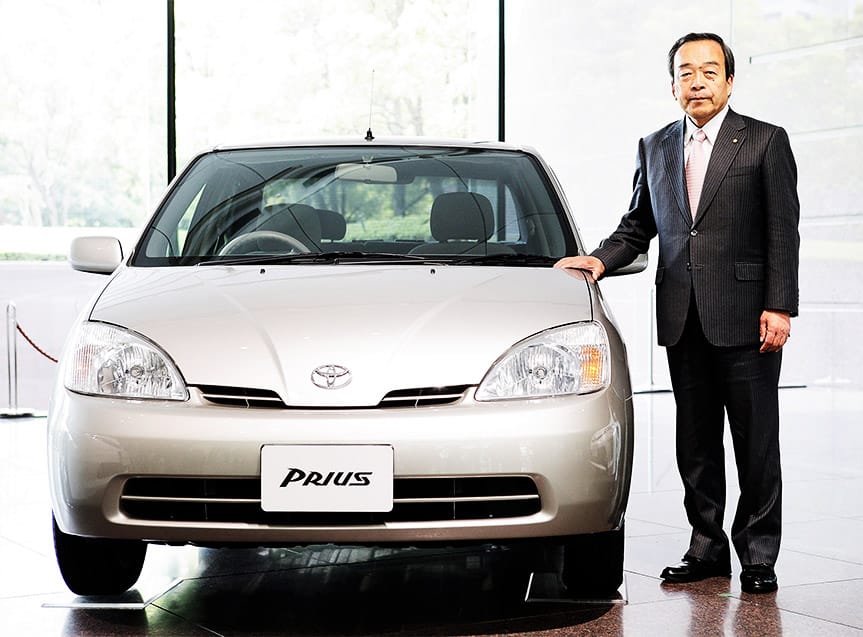

We spoke to Satoshi Ogiso, the only person to have worked on the Prius from the project planning stage all the way through to the current fourth generation. He told us about what led to the development of the very first Prius.

Satoshi Ogiso, member of every Prius development team since generation one

G21: It all started with the G21 project

"It was the summer of 1993," recalls Ogiso. "Eiji Toyoda, honorary chairman at the time, urged us to start thinking about a new vision for cars, one for the medium and long term that would prepare us for the 21st century. That's when we started the first study that would lead to the Prius."

Chairman Shoichiro Toyoda agreed with the plan to develop a new vision for cars and lent his support. The initial study commenced in September under the codename "G21." "G" stood for "Globe" and "21" for the 21st century, a fitting moniker for a project whose main aim was to conceive a car for the new century. The project team consisted of 10 engineers and designers, working off a blank slate on research for a next-generation mass production passenger car.

"One of the initial challenges was how to define this vague concept of a car for the 21st century," recalls Ogiso. "We couldn't rely on conventional methods, and since we couldn't adopt a market-oriented approach, we decided to propose a whole new technology."

By the end of 1993, the project team had compiled an initial report outlining the concept for a 21st century car. It was compact, but roomy, with a long wheelbase and a fuel efficiency of 20 kilometers per liter. With the report approved, the initial project team disbanded.

Soon afterwards, the G21 project resumed under a new structure led by current Chairman Takeshi Uchiyamada, then a member of the Technical Administration Division. The new mandate was to advance the research as a full-time undertaking.

Takeshi Uchiyamada, Chairman of Toyota Motor Corporation

G21 was officially launched on February 1, 1994. In addition to chassis, body, engine, and driveline engineers, production engineering staff joined the project. This wasn't a team built just for research: it was a team that could take an idea from design to production. They started by revisiting the fundamental question of "What is a car for the 21st century?" The discussion revolved around the environment, energy, and safety. By 1993, Toyota had already made great technological strides in car safety. Project members agreed that Toyota was now ready to face head-on the burgeoning issues of energy resources, global warming, and air pollution. The keywords behind G21 would be "resources" and "environment." The initial research team's notion of a compact car with a wide interior and excellent fuel efficiency reemerged as a core development concept.

"We thought about what kind of a car would match our concept from every angle possible," says Ogiso. "Would it be an ultra-compact car seating one or two people, or a large car with great fuel efficiency that could have greater benefit for the environment as a whole? In the midst of those discussions, we also considered the powertrain."

The early 1990s was a period in which carmakers around the world were striving toward a next-generation powertrain as the promise of electric drive was emerging. At this stage, however, the G21 project team didn't consider a hybrid system powered by an electric motor to be feasible. It was a hot topic, but the technology hadn't been proven.

"Even then, we practiced Toyota's current approach toward the environment, namely that no matter how good a car's performance is, if the technology isn't widely adopted, it can't benefit society," Ogiso notes. "At the time, we saw the hybrid as a technology that couldn't be achieved by the start of the 21st century. The whole team shared that outlook."

The G21 team settled on a direct-injection engine with a highly efficient automatic transmission that could raise fuel efficiency to 1.5 times a similar car in its class.

Then, the project's direction took a major turn.

Double the fuel efficiency!

In November 1994, Akihiro Wada, the executive vice president for technology, instructed G21 leader Takeshi Uchiyamada to make the next-generation car a hybrid. Wada emphasized if that wasn't possible, the project would be axed.

"At first, we were told to plan a hybrid version of the next-generation car as just a concept car for a motor show," relates Ogiso. "But gradually, the voices for making a production hybrid car grew stronger. Uchiyamada thought at the time it would be impossible to develop a production hybrid before the start of the 21st century."

Despite the doubts, a consensus grew that it would be meaningless to debut a 21st century car with a 20th century powertrain. Suddenly, the project faced a towering development hurdle.

"Fuel efficiency 1.5 times the conventional car wasn't good enough―we needed to double it," says Ogiso. "And we knew that was impossible with conventional methods, so the only answer was hybrid technology. If we weren't up to that task, G21 had no reason to exist."

Studies on a new hybrid system began in 1995. At the time, there were no accepted theories for proven hybrid systems, so the team's only option was to consider a range of hybrid systems and choose the best from among them.

Ogiso recalls the technical challenge. "We studied various systems for about six months from the end of 1994, before deciding that the two-motor type was the best option because of the high fuel efficiency potential. We assumed that power electronics (semiconductors and electronic circuits used to efficiently control power) would make leaps in the near future. There was a lot of promise here. The conventional transmission could be completely eliminated. And yet, the technological hurdles remained high."

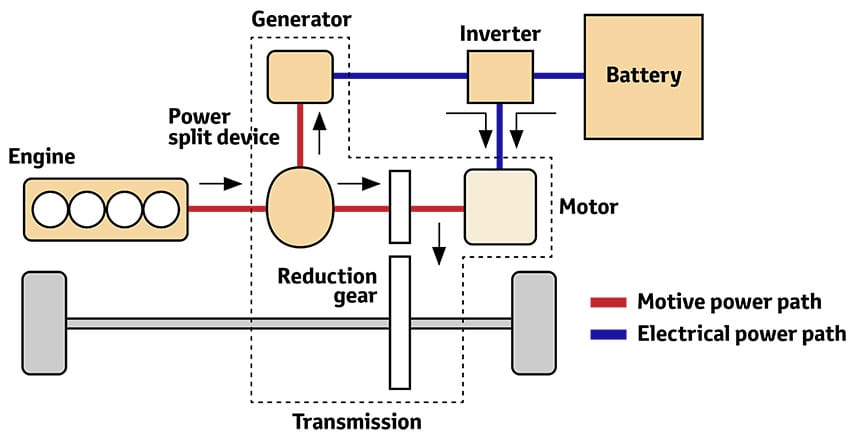

The system adopted by the team would later come to be known as the Toyota Hybrid System (THS), featuring two motors in addition to the engine. The drive motor would boost engine output while acting as a generator during deceleration to charge the batteries. The second motor would use the drive power of the engine to generate electricity as well as control the transmission. It would also be used as a starter motor. A power split device with planetary gears would connect the two motors with the engine. The input shaft and output shaft would be on the same plane to make the car more compact. The engine output would be divided between driving the vehicle and power generation, and the continuously variable transmission (CVT) would control engine speed. An inverter would also be placed between the battery and motor. This would convert the current between the direct current batteries and the alternating current synchronous motors.

The G21 team worked on the development of a concept car for the Tokyo Motor Show alongside their development of the production car.

"The system installed in the concept car featured a single motor, direct-injection engine, and CVT," recalls Ogiso. "There was a capacitor instead of batteries, and the targeted fuel efficiency was 30 kilometers per liter. Technically, it was a hybrid, but we called it the Toyota Energy Management System, or EMS, instead. We had already decided to use two motors for the new hybrid system, so we wanted to clearly differentiate the two cars. We did, however, start using the model name Prius from this stage."

Internal development of core technologies

The G21 team got the official go-ahead for the production car at a meeting in June 1995. Their first task was to create a prototype, and the initial steps would be to select the right engine and develop the motors and batteries.

Traditionally, in-house creation has been the guiding force in Toyota's acquisition and nurturing of its core technologies. The team didn't want to relegate itself to a mere vehicle assembler by outsourcing development of a key hybrid component like the motor. They also decided to develop the inverter internally. This also couldn't be an outsourced "black box" technology because it would control the hybrid system. For the battery system, the team decided to collaborate with Matsushita Battery Industrial Co. Ltd., with which it had collaborated on electric vehicle research.

"For the prototype, we were working off a completely blank slate," says Ogiso. "We started by assembling the basic parts and testing them. Each one was tested on a test bench and then we incorporated computer programs. None of the major components had a track record, so it was a real challenge making that first car."

The goal was getting the car to market before the start of the 21st century. Time wasn't on their side. Beyond the hybrid system, there were many other tasks to deal with. The design had yet to be decided and the suspension was an urgent issue.

In August 1995, Hiroshi Okuda was appointed president of Toyota Motor Corporation. The appointment proved an important event not just for corporate management, but a turning point for hybrid car development, as well.

Continue to Part 2